This machine is used in medicine packing ,carries

on the technical improvement and the implementation

GMP production equipment, the product has been sold to

the domestic and foreign each big pharmaceutical factory

and the large, the medium hospital, and exports more than

20 countries and the region, received the customer favor

and the high praise.

and the whole set of equipment conforms to the international pharmaceutical GMP standard.

Vial Filling Machine uses vertical drum structure. Transport mesh belt feed the bottle with screw. Clip the bottle, and turn it around by mechanical arm in continuous rotation. Washing spray pipe does swing and track movement repeatedly. Spray water and air alternately when the bottle is in upside down, and use ultrasonic washing. It has excellent washing effect. Machine is made up by bedplate, drum, screw lifter, transmission gear, water pump, filter and etc. After water injection, bottles move to water channel for 1 minute ultrasonic washing. Then screw sends bottles to lift wheel. Mechanical arm clip them and turn 180 degree to upside down. Wash them by water and air alternately.

All the cleaning fluid contacted parts use SUS 304 and non-toxic corrosion-resistant material. All working area use PC glasses. Prevent from the outside pollution. Machine has the ultimate filter. It makes cleaning water and compressed air reach the cleaning washing requirement.

Vial Filling Machine uses AC motor drive, frequency speed control and PLC control circuit. It has reliable performance. Water in tank has automatic constant temperature control with water level control switch. It prevents the machine from pump, ultrasonic and heater turning on in waterless condition. Pipeline has pressure display. Adjust the pressure by diaphragm valve.

Vial Filling Machine can receive the signal from sterilization oven, filling and sealing machine. When bottle is in jam, machine will turn off automatically.

This machine is mainly used in pharmaceutical industry for drying sterilization for ampoule, vial and oral bottles.

This machine automatically feed, pre-heat, drying sterilize, cool and outcome the bottles. It uses laminar flow and hot-air fast sterilization. It makes bottles arrive National Clean Class 3 (American Industry Class 100) in the tunnel. It is the most fashionable and effective drying sterilization equipment. The heat distributes equally, and it has good effect on the heat removing.

This machine can be used separately, and it can also be used with bottle washing machine and filling machine in the production line.

1. Speed regulation with frequency conversion and mechanical traction;

2. Adjustable stroke, adjustable range of 30-100mm, convenient adjustment, accurate synchronization;

3. It is standard equipped with four stations (molding, heat sealing, indentation and blanking) and installed with four columns for each station, making the adjustment more convenient and stable;

4. Plate mold, positive pressure molding, batch number, indentation and tangent, aluminum foil/aluminum automatic hair;

5. Equipped with a set of universal feeder, the filling rate is up to 99.5% or more;

6. Small size, light weight, adjustment and maintenance space, etc.

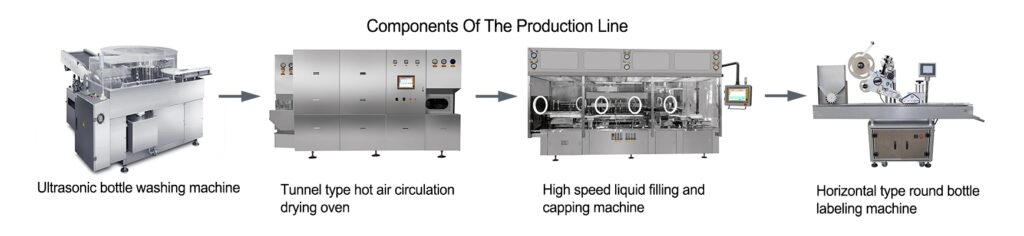

Vial Filling Machine Production Line consists of ultrasonic bottle washing machine, high temperature dryer, high speed filling and stoppering machine and cap rolling machine. All parts are closely connected, the operation is safe, stable and efficient, and the whole set of equipment conforms to the international pharmaceutical GMP standard. Vial Filling Machine Production Line consists of ultrasonic bottle washing machine, high temperature dryer, high speed filling and stoppering machine and cap rolling machine. All parts are closely connected, the operation is safe, stable and efficient,

© Your Site Name. All Rights Reserved.